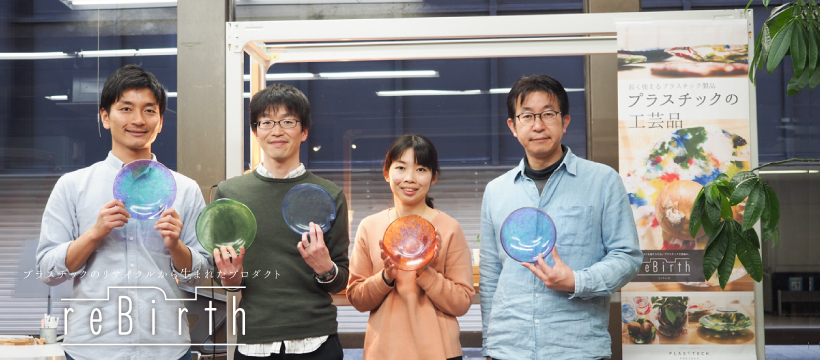

We have desired to make a plastic product which people use and love for a long time. Therefore, we created “reBirth” products that are one and only plastic dishes. Molding resin products is a method for mass replication of the same shape. However, the manufacturing technique of “reBirth” keeps a room to express uniqueness to every product in terms of shape and design.

Introduction・Greeting

A group of volunteers from Techno-Labo co., Ltd. started the Plas+tech project. We aim to develop products that can pose a problem to society regarding the future of plastics in terms of both technology and design.

Product

The “reBirth” is our first project started by the idea that collects and transforms marine litter, which is a significant problem in society, into the items people use and love for a long time.

We often use plastics as disposable items, but it has advantages like water and impact resistance. We make use of these features of plastics and make ”reBirth” products that people can use repeatedly and love for a long time.

Plastic is reminiscent of mass production, but each “reBirth” is a handmade product. The design of each product varies in the types of collected marine litter, the arrangement of raw materials, the climate conditions, and the creator. It features the unique texture of plastic that is neither glass, ceramic, stone, or metal do not have.

Characteristics of Product

■The One and Only Plastic Dish

Plastic material is suitable for duplication by using a mold. However, if it does not meet strict quality standards, it will be treated as a defective product. As the time changes from mass production era, there is a growing need for “things” that individuals can use and love for a long time rather than similar products that anyone can buy cheaply.

Under the theme of making the one and only plastic products, we apply the unique manufacturing technique, which keeps a room to express uniqueness to every product. Colors and shapes are accidental and unduplicable.

We have the hope that users will use only one product in the world for a long time. At the same time, we would like to break the stereotype regarding plastic.

■Designs Made from Technology

We are making this product by our original manufacturing method based on the technique of heat press.

We usually manufacture plastics by heating little granular materials called pellets. The design of “reBirth” expresses how the machine pressed the pellets.

Another feature is the pattern of the compressed pellet spreads along with the shape of the product, by forming the product twice.

■Aiming for Plastic Product People Use for a Long Time

Plastic is a cost-effective material to manufacture in large quantities. However, considering the price alone would produce many wastes. Cost is not the only advantage of plastics. We can handle a plastic product repeatedly and hardly break it, even when using it roughly. We can adjust color and shape easily. Even a family with a little kid can use a beautiful plate without any concerns to break it, unlike glass.

In this project, we aimed to develop plastic products that users would like to use for a long time. While adopting user opinions, we have designed products that take advantage of the characteristics of plastic.

Development Background

Molding method different from usual

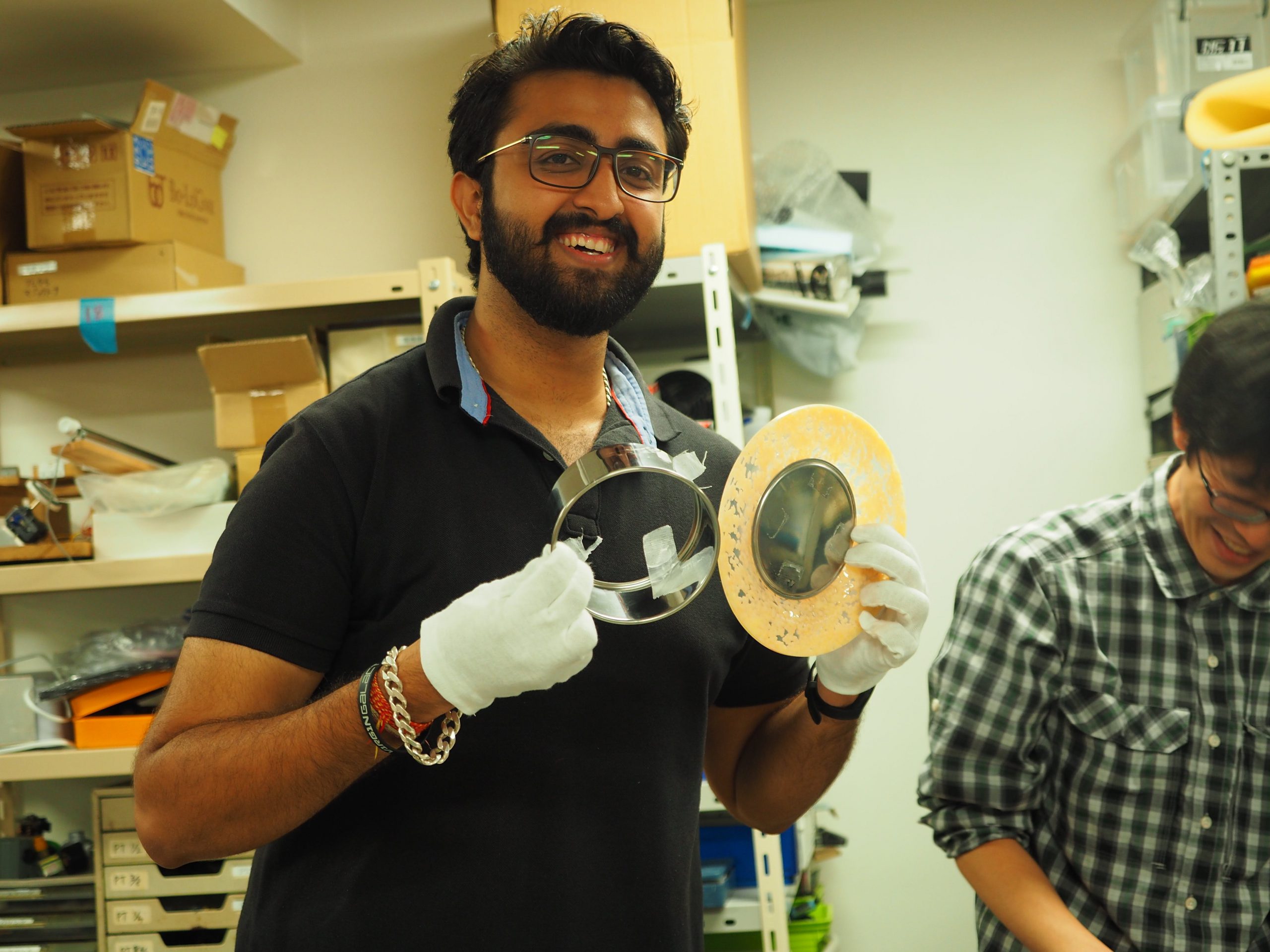

We are usually making plastic products by the method of injection molding. About a year ago, marine litter became a hot topic within our company, and we discussed how to recycle them. In the discussion, an opinion came out that “I want to create a product that shows the characteristics (= color) of the original product before recycling, rather than changing ocean plastics to something completely different.”. Then, the CEO remembered his experience to learn the method of press molding at university and thought that he could create appealing textures with that method. Hence, we started research on this method.

We started from the procurement of the press machine for a reasonable cost, and learn its operation. It was tough to figure out how to use it.

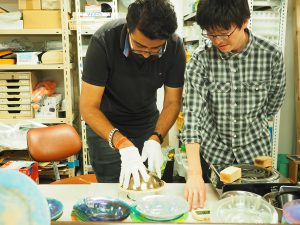

Molding a dish from resin usually completes forming in one time. However, we aimed to manufacture the products by hand, not only by using a press machine. Consequently, we perform forming the dish by second molding.

We developed secondary processing as anyone can join in. The expression will be slightly vary depending on the character of the creator.

Our intern also tried forming. You can see his sensitive personality a lot by his delicate dish.

Opened stores in flea and creator markets and improved design based on advice from customers

Since our main business is the development of industrial equipment, we do not develop products for consumers. Therefore, we made trial products using virgin material (non-recycled material) before making a product using ocean plastics. Then, we actively participated in the event to listen to advice from users. Although we have participated in B2B exhibitions before, it was our first time to open a store in the flea market or the creator market. We were excited that people enjoying the holidays would visit our store to see our products.

Despite the efforts to attend the event for a whole day, only a few customers checked our product, and some people complained about their low quality. However, as some customers asked for purchases, we were more willing to work on the project.

As we participated in more events, we got feedback from the customers such as “I prefer the other size.”, “I’d prefer more colorful design as a fruit dish so that my room would be blighter.”, “I have kids, so I like these products because of their durability and variety of colors.”. We gradually improved our products according to this feedback and progressed our project.

Use of Funds

We will use the funds raised in this crowdfunding mainly for the event of collecting marine litter. The members who live in Yokohama and Zushi have been working on this project. At first, we wanted to produce the dishes from marine litter collected in Zushi and Shonan area. However, while investigating the marine litters of Japan, we learned that there are places where these wastes easily drift due to the influence of tides.

Therefore, we would like to go to an area where there is a lot of drifting trash and hold a beach clean event to collect materials. We make crowdfunding rewards from marine litter collected at the workshop. Along with rewards, we will send you pictures of the workshop, and pictures of marine litter used for making rewards.

Team Introduction

Techno-Labo co., Ltd. is the company that designs and produces plastic products. We have shaped the ideas of people who desire to make their ideal products or develop new products for their users so far.

We believe that there are manufacturable products and resolvable problems by utilizing the characteristics of plastic. On that thought, we are working on asking society how to face the use of plastics.